INTRODUCING THE

Built-World Revolution.

Patented 3D-printed fabrication technology.

Unprecedented design freedom.

The parameters of

spatial design are shifting.

We’re at the forefront of that change.

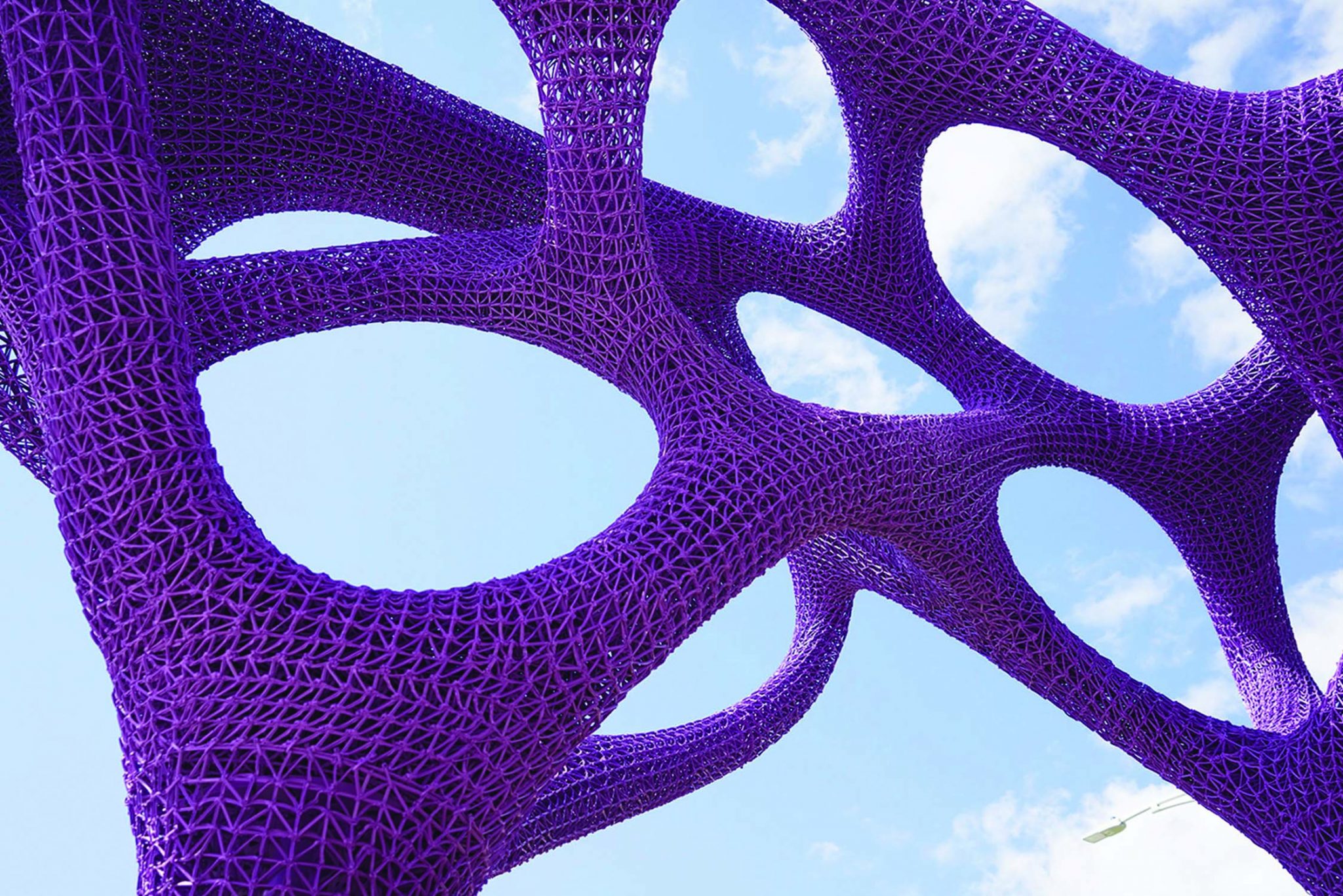

For the first time ever, we’re combining additive manufacturing, prefabrication, and digital technology at construction scale. Using our patented technology and digital fabrication process, we’re enabling architects, designers, and innovators to imagine, compose, and construct complex design structures previously thought impossible using traditional construction methods.

Products

Powering unimagined

design possibility.

OUR PATENTED TECHNOLOGY

What if you could Build Like Nature™?

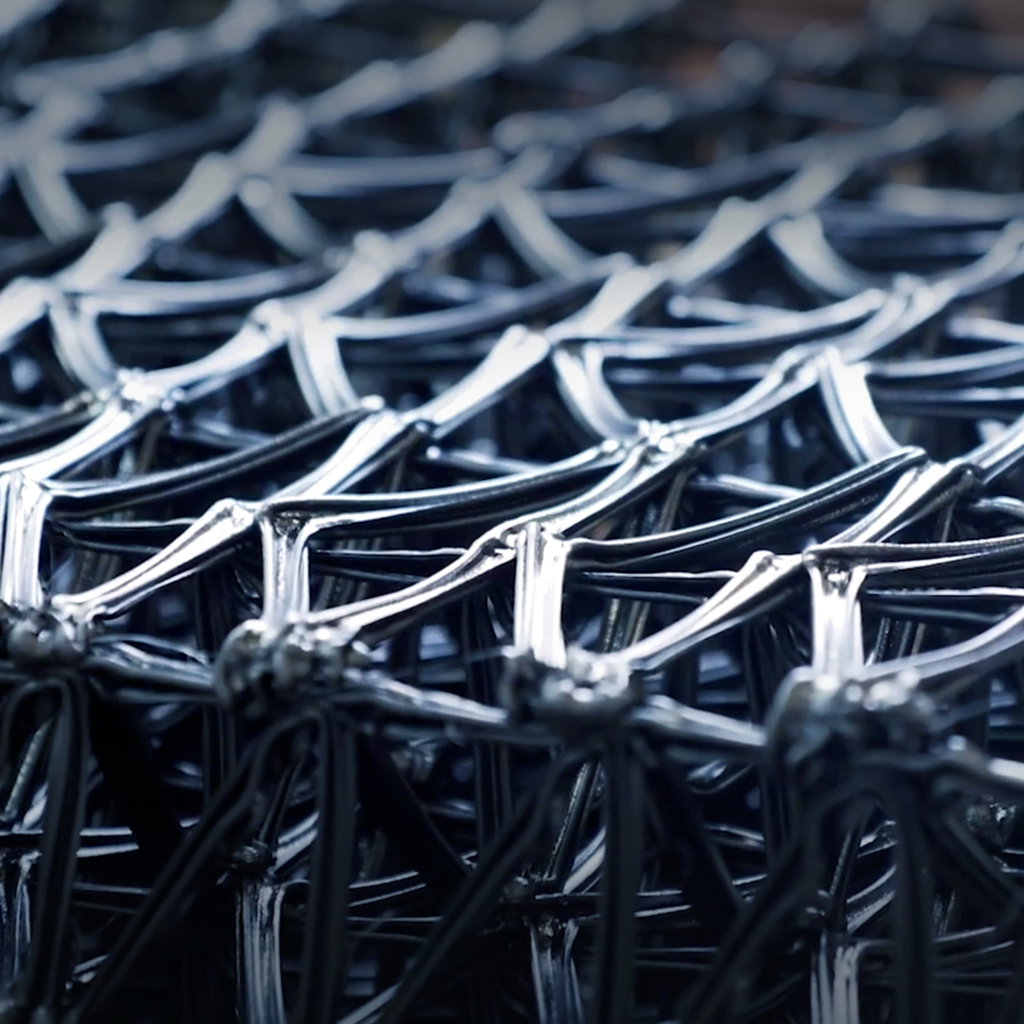

Inspired by nature’s efficiencies of cellular structures, our construction-scale, freeform 3D-printing technique and direct digital manufacturing approach is a world-first. We call it cellular fabrication, or C-Fab® for short.

Feature

Projects

BranchClad™

3D Printing Technology Takes Center Stage in Downtown Huntsville, Alabama